Factory Simulation develops digital twins through advanced simulations to reveal how your production truly performs.

Projects

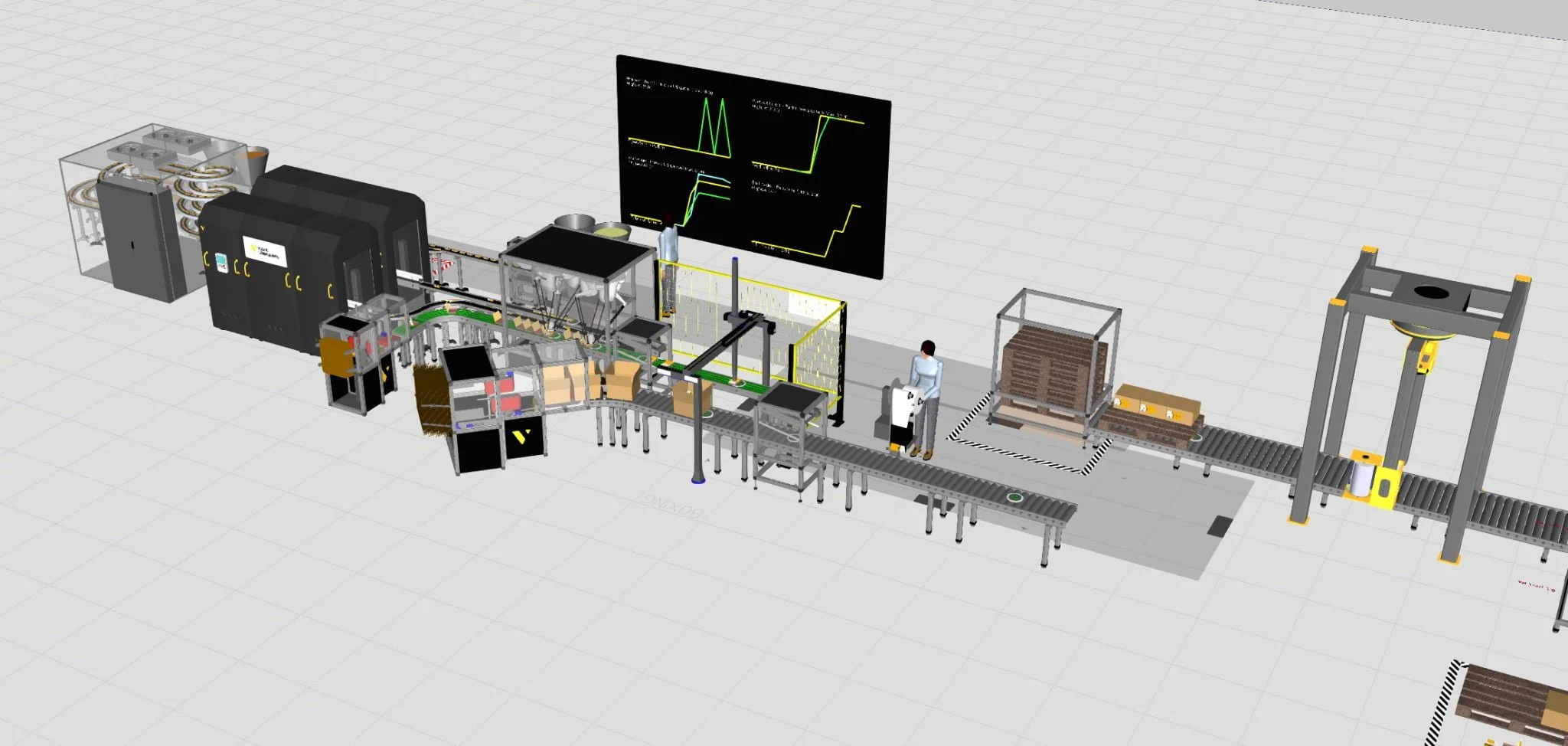

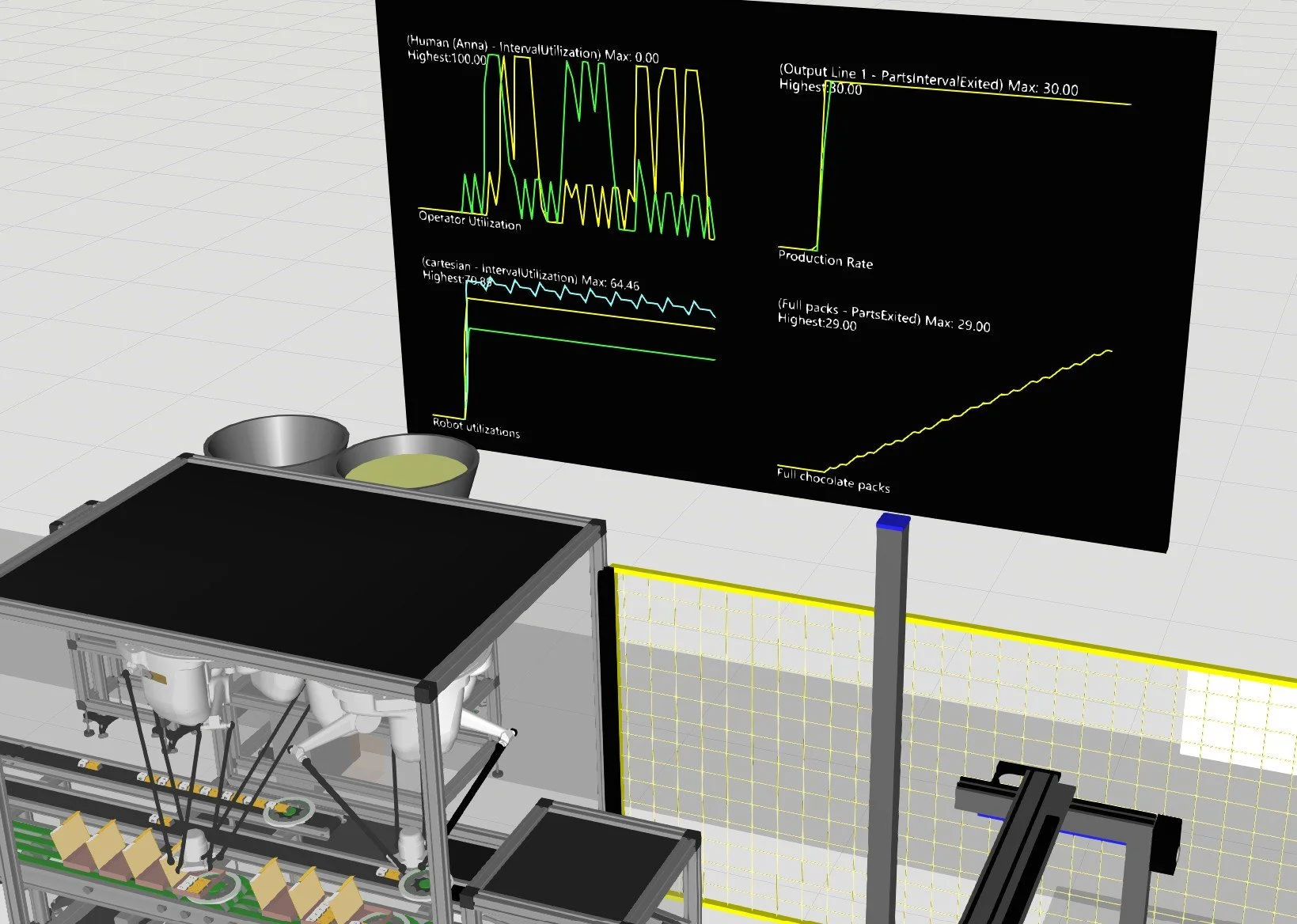

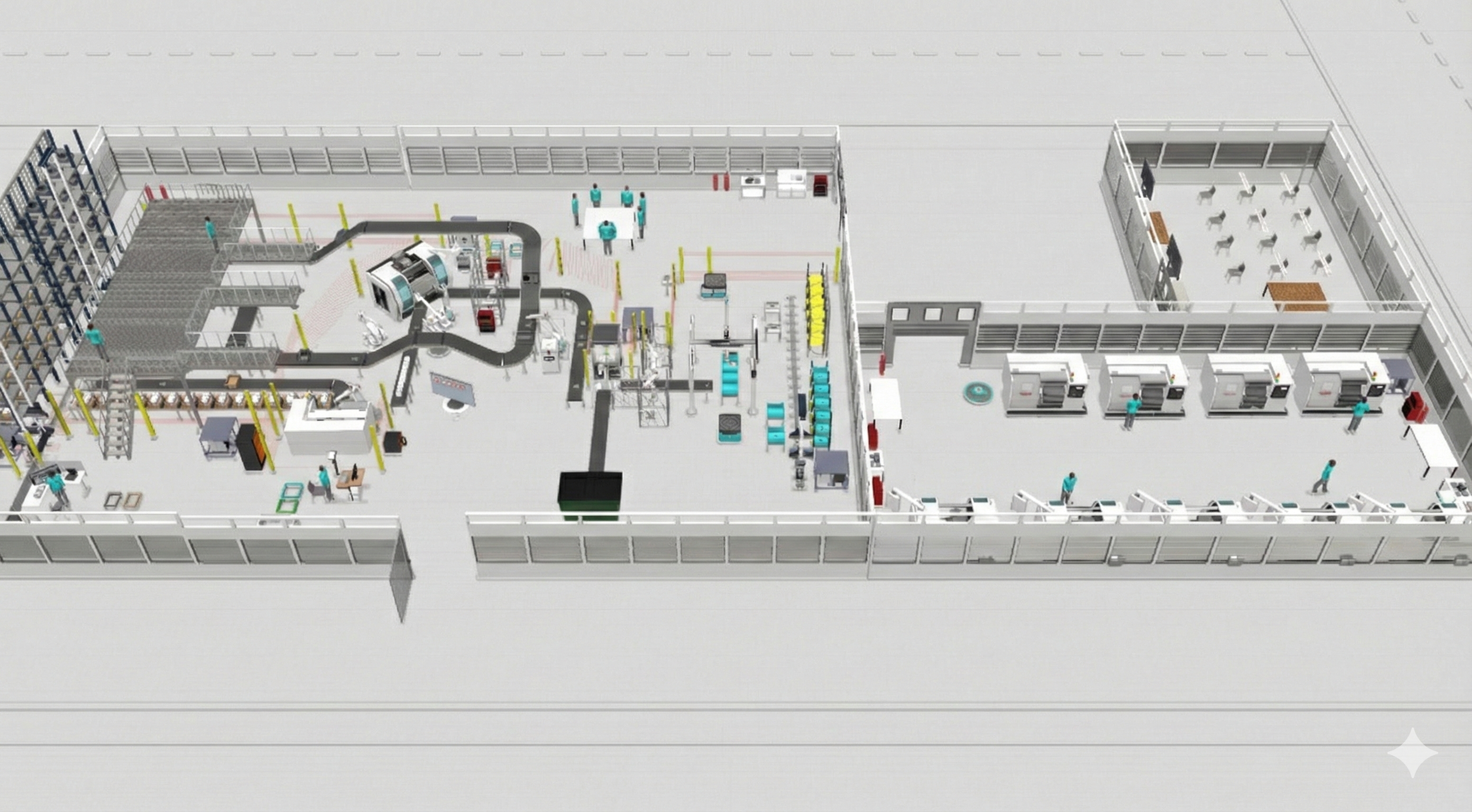

Protein bar manufacturing process

Explore

95% robot utilization – optimized task sequencing boosted equipment use.

35 → 38 units throughput – output increased without new machinery.

40 → 120 packs – packaging performance tripled after bottleneck removal.

+20% operator productivity – better workload balance reduced idle time.

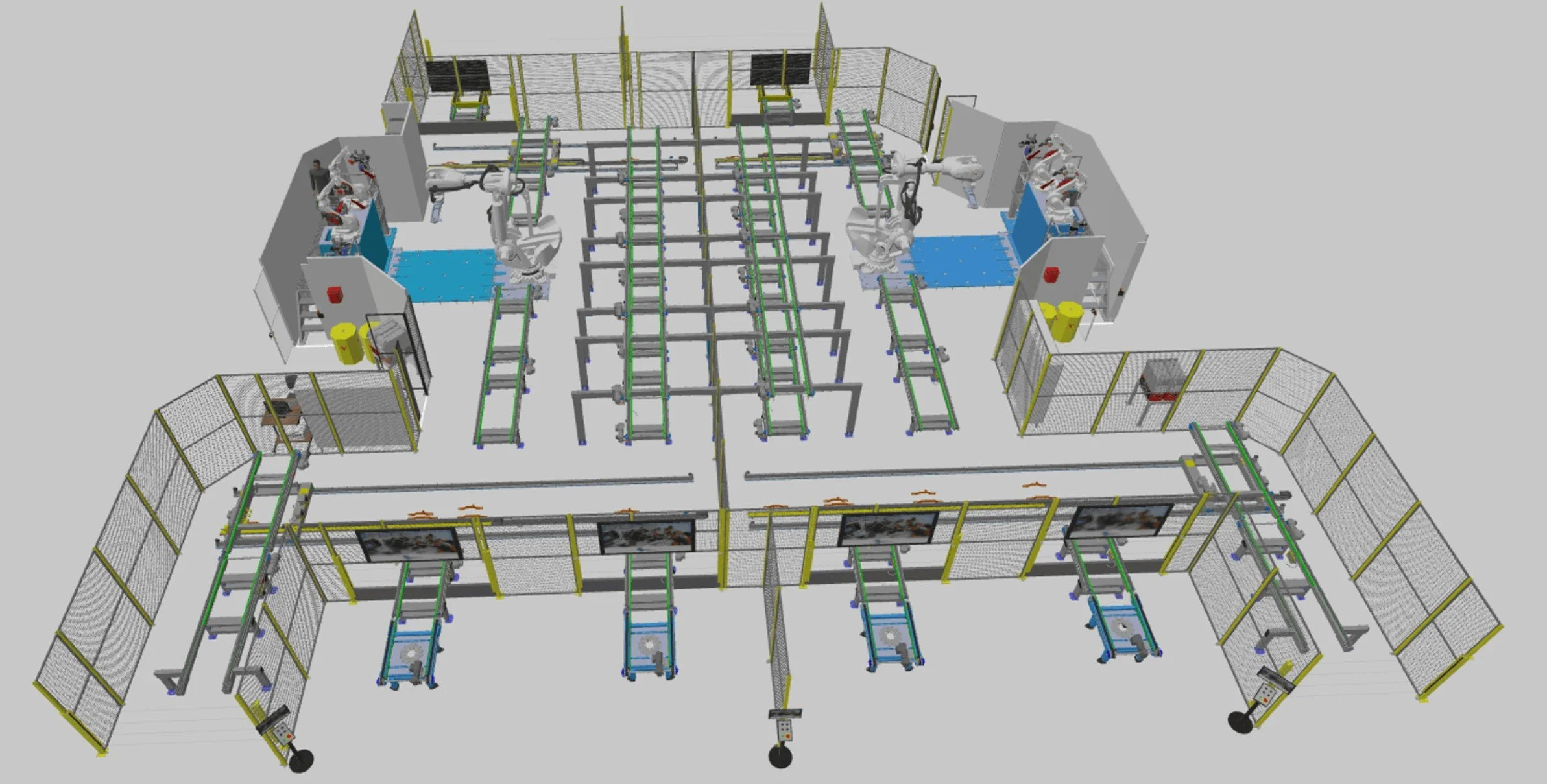

Elevator parts assembly

Earlier project start – planning began long before equipment arrival.

Unified stakeholder view – one accurate 3D model for engineers and management.

Faster ramp-up – reusable layouts sped up concept validation.

Lower implementation risk – virtual testing prevented costly design errors.

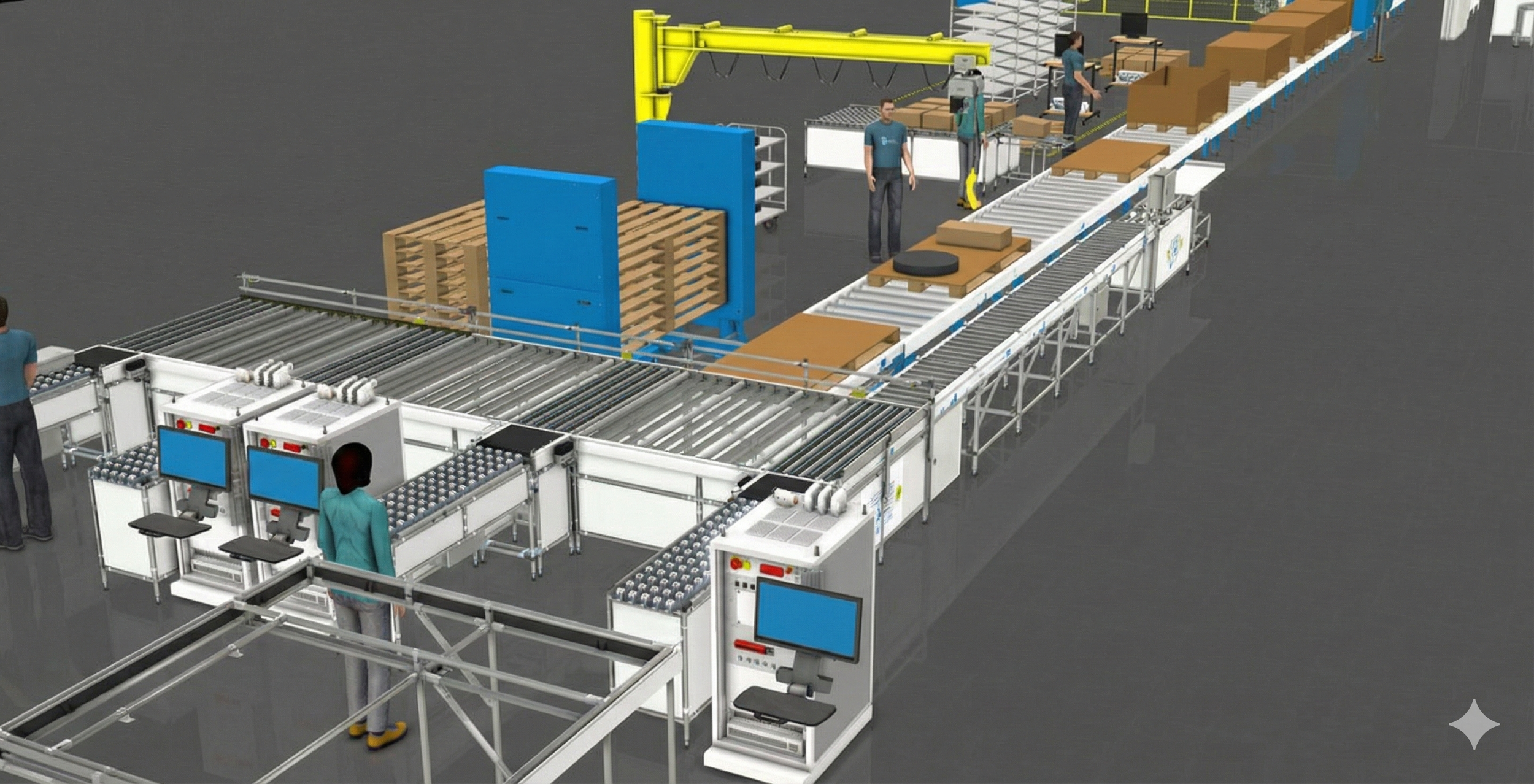

Robot cell automation

Up to 50% faster robot programming – programs built and tested virtually without stopping production.

Higher program quality & safety – reachability, collisions and fixture concepts validated before deployment.

Scalable automation platform – supports adding new robot cells and AGV/AMR solutions with lower risk.

Let’s work together!

From early-stage concept to validated factory plan, we help manufacturers make confident decisions.

About

Services

Factory layout simulation

Production flow & bottleneck analysis

Scenario testing for investments

Locations

Estonia

Partners

AIRE (AI & Robotics)

Visual Components

Clients

Industrial manufacturers

Food and beverage industry

Machine builders